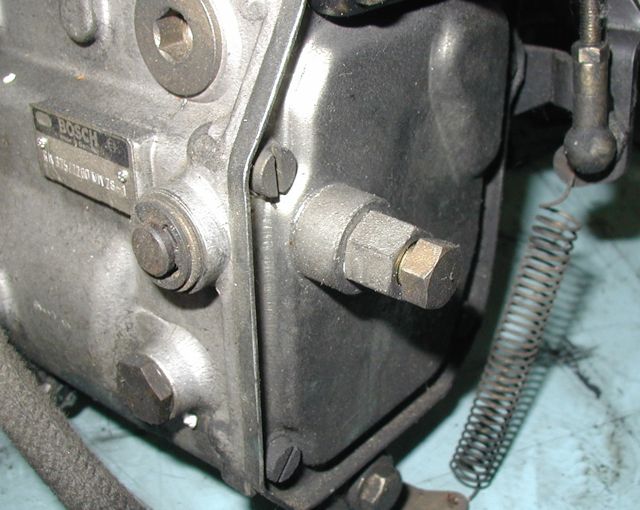

Overview: The purpose of the rack damper bolt (very center of picture) is to smooth out oscillations of the injection pump fuel delivery rack at idle. The spring on the original bolt was long and thin and it required turning in considerably (after making first contact with the rack). The spring would fatigue over time and correct adjustment became impossible. Any adjustment would end up being unstable as the spring heated, cooled and fatigued. A new upgraded rack damper bolt is available that has a much thicker spring, and its adjustment is much more stable over time.

Problem & Solution

Common among these chassis:

Location: The rack damper bolt location is at the lower back of the fuel injection pump assembly. You will see it sticking out the back of the pump housing. It appears there are two hex nuts. The outboard one is actually the rack damper and the inboard "nut" is for locking in place. (You will not find the rack damper on the 1978 to 1980 116 300SD turbo engine unless the engine or the pump has been changed).

Installation: You will need two short wrenches (14 mm open end and 12 mm box end). Loosen up the inner locking nut and turn the rack damper bolt counterclockwise to remove. Take the locking nut and the o-ring off the old rack bolt and place it on the new bolt, turning the nut in as far as you can. Now insert the new rack damper bolt and turn it in by hand until you just begin to feel it make contact. Go ahead and tighten the locking nut down snug (but not too tight).

Adjustment: Adjustment is made with the engine running at operating temperature. While the engine is running listen and watch carefully to see if the engine is "rocking". It may even be changing speed pitch ever so slightly. The goal here is to turn the rack bolt in the least amount to stop the engine "rock" and smooth out vibration. It may take a few attempts of "playing" with it until you get it adjusted just right. Make sure you securely tighten the locking nut. Note: If you turn the bolt in too far, starting the engine may become difficult or nearly impossible.

If adjustment of your old rack damper does not help, I recommended you install the upgraded version to improve performance. These upgraded rack damper bolts are available on our website. If you experiencing an oil leak in this area we also have the special o-rings available separately. See related products to order.

Follow-up: If repeated attempts to adjust your NEWLY INSTALLED rack damper bolt, does not smooth out your engine, then you will need to look else where for the cause. Here are some other things that should be checked that can cause rough engine idle.

1. Compression: weak cylinder

2. Valves out of adjustment or valve timing (stretched chain)

3. Dirty fuel filters or plugged air filter

4. Poor fuel quality

5. Bad injection pump delivery valve(s)

6. Bad injector(s)

7. Injection pump timing

8. Worn out mechanical lift pump

9. Problem with injection pump itself (this should be the last thing you check).

For more information on follow-up please read my repair guide Mercedes Diesel Performance Tuning and Maintenance