German made for us by Wolfswerke-sachsen ( by same company and same nozzle that was formerly branded as Monark). Yes! We brought them back...

Product Details

Fits the following: These nozzles fit 1986 to 1993 603 Engines and 1987 (only) 124 chassis 300D and 300TD. Also fits 1994-1995 S350 ONLY. This is the critical inside wear part of the injector that delivers the fuel spray into the cylinder. Replace for better fuel economy, more power, easier starts, and less exhaust smoke.

WILL NOT fit 1995 E300D!

12 month warranty provided on Nozzles when all assembly precautions are followed (as detailed in included instructions).

We want to help you get your diesel performing better. If your injector tips are worn out here are my recommended replacements. These injector tips are made in Germany and they are designed with a finer mist pattern than that produced by the Bosch tips. My experience has shown that these tips work better (fuel burn) especially on higher mileage diesels with less than perfect compression numbers. On my own diesels I have also noticed less injector nailing (pinging noise) with these tips installed. Always replace the crushable heat shield washers when replacing your fuel injectors.

[Fuel injector easily disassembled for nozzle replacement] Fuel injector easily disassembled for nozzle replacement

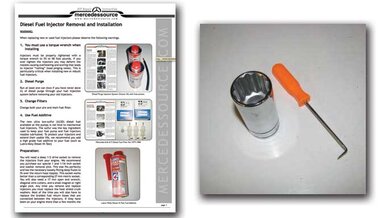

Partial PDF instructions are included - covers installing new nozzles in injection holders - but does not cover removal from engine or injector pressure balance testing. If you want complete detailed instructions for all things related to removing injectors, cleaning used injectors, checking spray pattern and balance pressure adjustment, then I would strongly recommend you purchase my complete manual Diesel Injector Cleaning and Testing Procedures.

_______________________________________________________________________________

How to view the PDF digital instructions:

Once you complete the purchase of this product you will be able to download the digital instructions immediately when you are logged in and on your personal account page (click on My Account). Any PDFs will show up under My PDF Manuals. You will be allowed three downloads, so please save the file on your machine for backup.

_______________________________________________________________________________

Ideally you should pressure test and set the correct release pressure when installing new tips. If there is a Bosch repair facility near by you can have them do this testing/adjusting for you. You can install these tips without checking adjustment and in many cases they will fall into an acceptable pressure/spray pattern range. This might be preferable to badly worn out fuel injectors - but best to test pressures and balance injectors if you can.

[New tip design produces spray pattern with better atomization (fine mist)] New tip design produces spray pattern with better atomization (fine mist)

IMPORTANT NOTE: If you are running SVO WVO or B100 these have the highly touted DN OSD 265 specification for the 603 engine. These have a newly designed tip for modern fuels. Bosch tips have some horizontal and vertical bores in the tip. These easily plug up with running SVO or B100. With these injectors you do not have that problem and they produce a finer spray pattern for better combustion. Many, including myself, have reported great results when running heavier viscosity fuel. I consider these a must have if you are running waste vegetable oil for fuel.

ADDITIONAL ITEMS NEEDED: Anytime you remove and replace your injectors you must replace the heat shield washers under the tips which are included with this purchase. You will also more than likely need to replace the rubber fuel return hoses connected to the injectors. Trying to reuse the old hardened hoses almost always result in leaks.

I recommend you have a torque wrench handy when rebuilding your injectors. If not we offer one at a great price. [Use a torque wrench when cleaning or rebuilding injectors] Use a torque wrench when cleaning or rebuilding injectors

HIGHLY RECOMMENDED: You will need some fine sandpaper to lap in your injector parts during rebuild. We have an kit available separately that will assure your injector halves don't leak when you put them back together. Instructions and tips are included.

Note: This kit can also be used to fix a pesky leak on your existing injector

WARNING:

The health and longevity of your new injector nozzles with be directly affected by the cleanliness of your diesel fuel and its lubricity. Any gunk or crude in your filters or injection pump could travel to the new nozzles and cause scoring leading to premature failure (our warranty does not cover nozzle tip scoring). The following procedures are a MUST with installing new nozzles:

1. Diesel Purge

Run at least one can (two if you have never done it) of diesel purge through your fuel injection system before removing your old injectors.

2. Change Filters

Change both your pre and main fuel filter.

3. Use Fuel Additive

The new ultra low-sulfur (ULSD) diesel fuel available at the pumps is not kind to mechanical fuel injectors. The sulfur was the key ingredient used to keep your fuel pump and fuel injectors lubricated. To protect your new nozzles we recommend you add a high grade fuel additive to your fuel (such as Lubro-Moly Diesel Hi-Test)